Also known as 3D printing, additive manufacturing has been making waves in engineering circles since the 1990s. As the technology matured and entered the mainstream towards the end of the noughties, more and more businesses began waking up to the many applications and potential revolutions 3D printing can offer.

We ask what 3D printing really is, why it’s such an important development, and what might come next for businesses through this revolutionary technology.

What is additive manufacturing?

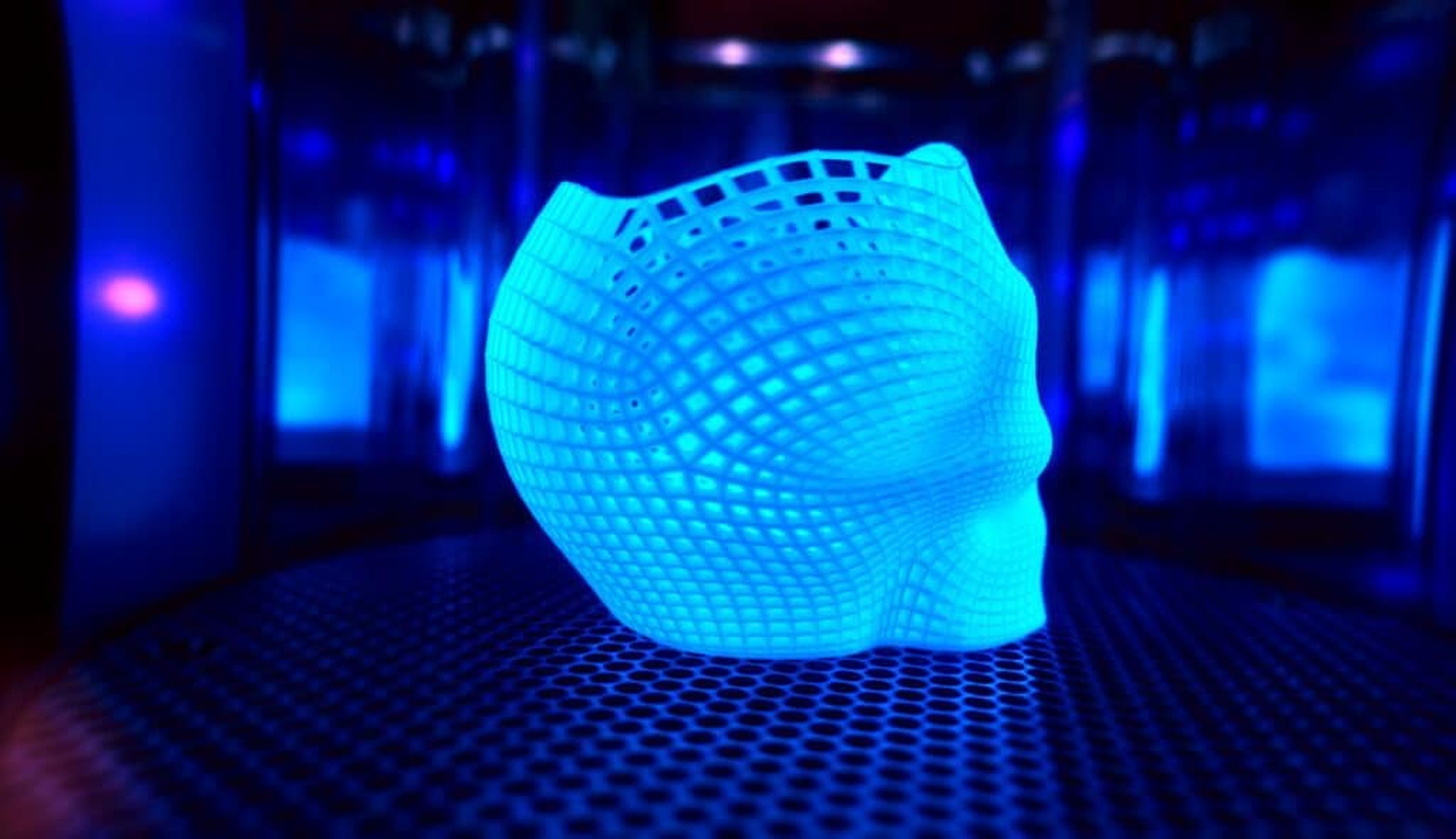

The term ‘3D printing’ covers a family of different manufacturing technologies. Which type is used depends on the desired finish, function, and size of the item being printed. Although slight differences exist between printer types, the process of additive manufacturing always begins on a computer; a digital object, or computer-aided design (CAD) representation, is created and then the 3D printer gives it physical form. Additive manufacturing is so named due to the process used to create 3D printed objects; production is carried out layer by layer, ‘adding’ more material in thin layers with each print rotation. This process contrasts with traditional subtractive or molding/casting manufacturing.

Compared with traditional manufacturing methods, 3D printing’s appeal is that it offers a quick, easy, and tool-less way of turning a digital image into a physical object in a matter of hours. Costs and lead times are vastly reduced, and designers can now create ‘rapid prototypes’. The ability to create individual objects on demand means that design changes can be implemented with each iteration, effectively streamlining the product design process.

Why is 3D printing a game-changer?

First patented in 1986, 3D printing is far from a new invention. Many leaps forward have been taken in the interceding decades, today’s iteration of the process having been developed from the 2010s onward.

As the technology reaches maturity, costs have plummeted. A basic 3D printer can now be acquired for a fraction of the cost of the latest smartphone, making additive manufacturing cheap, accessible, and available for just about any application you can think of. Such ease of access has led to increasing experimentation with 3D printing, with new applications and innovations coming thick and fast from a wide variety of sectors and industries.

Medical advances

Human trials are an essential part of medical development and innovation, but recent social distancing requirements and safety concerns have severely impeded normal medical research operations. Scientists from the University of Leeds and the University of Edinburgh found a novel way of circumventing these challenges; 3D printing a synthetic human tongue.

The ability to produce accurate replicas of tongue surfaces with similar structure and mechanical properties will help streamline research and development for oral care, food products and therapeutic technologies

The promise of further research in this area could have significant consequences for medical communities across the globe, since access to synthetic body parts could not only speed up the development and testing of new medicines, but could also be used to personalize medical care.

Medical implants, such as knee replacements and coronary stents, can be tailored to a patient’s anatomy, and trials are already underway to print human organs suitable for transplant.

Space exploration

NASA first sent a 3D printer to the International Space Station in 2014. They found that a microgravity atmosphere had no significant impact on the printer’s capabilities, effectively opening up a world of possibilities for the astronauts who man the space station. Being able to create spare parts, supplies, and other necessary cargo on the space station would drastically reduce the need for regular resupply missions and could eventually allow space exploration missions to be conducted independently from Earth.

3D printing may prove to be the key that unlocks space for more than just astronauts. For every additional kilogram of a rocket’s payload, launch mission costs increase. The ability to launch with only the bare essentials – plus a 3D printer – on board could take us one step closer to commercial space travel; driving down costs could make space tourism a viable option in the near future.

It is hoped that the ability to manufacture in space will also facilitate construction; Project Olympus, a NASA collaboration with private firms BIG, SEArch+, and ICON, aims to create a sustainable habitat on the moon. The project will use robot-assisted 3D printing technology and lunar resources to create livable structures without the need to transport building materials or architectural specialists into space, vastly reducing both the cost and risk of such a venture.

We believe that 3D printing with indigenous materials is not only a fantastic practical solution but will prove to be critically vital to our species’ survival both here on Earth and in Outer Space

Food

3D printing and mealtimes may not be the most obvious bedfellows, but strides are being made to embed 3D printers into the kitchens of tomorrow. Already used off-planet – Israeli startup Aleph Farms oversaw Russian cosmonauts’ creation of 3D printed meat in 2019 – the potential for culinary 3D printing is still being explored.

Food Ink claims to be the world’s first 3D printing restaurant, where everything from the food to utensils and furniture has been created using additive manufacturing processes. However, current menus of 3D printed food are limited to what can be created using paste-like base ingredients such as purées, mousses, and other viscous foods such as chocolate ganache. This makes 3D printing a perfect fit for patisserie products, such as the 3D printed “artistic delicacies” created by the French Culinary Institute in partnership with Cornell University.

It is hoped that as the technology matures, at-home 3D printers will allow consumers to download and print meals from their favorite chefs or restaurants. Personalized nutrition is closely linked to the next stage of 3D printing technology, with experts predicting that individual dietary needs could be addressed through linked IoT health data, such as calorie needs, allergies, vitamin and mineral requirements, etc. Experts admit that the software and hardware required for such personalized processes, like printers which can cope with more solid foodstuffs, is still some way off, but it is hoped that this next generation food technology isn’t too far away.

What is the business impact of additive manufacturing technology?

3D printing is predicted to grow at an annual rate of 23% for the next seven years, leaping from a value of $5.8 billion in 2016 to $55.8 billion by 2027. Clearly the technology is taking off, but what will this mean for businesses?

Of all the innovations 3D printing has made possible, the one with the most potential to disrupt business models is direct manufacturing. Effectively shrinking the supply chain, direct manufacturing capabilities will enable companies to drastically reduce inventory through printing on-demand, as well as facilitating the consolidation of suppliers as parts and supply needs decrease.

Widespread adoption of additive manufacturing methods would also help to reduce waste and companies’ carbon footprint; very little raw material is wasted during 3D printing, and the ability to manufacture objects locally necessarily reduces logistics and transport emissions.

Furthermore, if 3D printing technology becomes as commonplace in households as some experts predict, businesses will be forced to reassess their value chains and product offerings across the board. Selling digital product designs for consumers to print at home would be a huge departure from normal business operations; there must be a concerted effort to ensure that value is captured across new product, service and delivery offerings as well as through revenue models.

Amaris Consulting helps businesses to unlock the full potential of additive manufacturing, from strategy development to implementation and change management.

Find out more about our 3D printing capabilities at Amaris.com.